Digital Manufacturing

for Automotive Product

Development

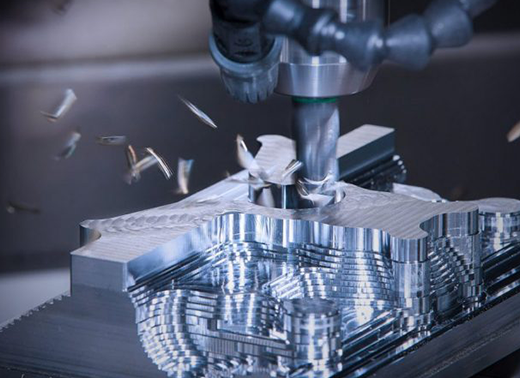

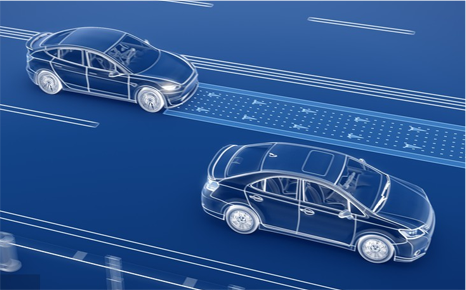

Conquer ever-shortening development cycles for traditional, electric, and autonomous vehicles with rapid prototyping and low-volume production

The automotive industry is evolving fast. As industry trends like autonomous driving, on-board connectivity, and hybrid/electric vehicles continue to drive innovation, agility-minded automotive companies are turning to Protolabs to accelerate new product development and get to market faster. With quick-turn digital manufacturing and automated manufacturability feedback, designers and engineers can mitigate design and cost risks while developing a more responsive supply chain to better react to driver and passenger demand for more customized vehicles.

Within the automotive industry, the malfunction or failure of a component can lead to catastrophic consequences. As such, it essential to fully test and evaluate any new part or product to determine whether it performs as intended before it is available in the market. For these operations, prototypes are ideal.

At 3ERP, we have extensive experience prototyping and manufacturing automotive parts, including for leading automotive companies such as BMW, Bentley Motors, Lamborghini, and Land Rover. We utilize rapid prototyping techniques to produce high-performance physical prototypes designed and built to pass some of the most rigorous verification and testing procedures available.

We produce prototypes for many interior vehicle parts, such as the steering wheel, dashboard, or console. By utilizing rapid prototyping, interior parts can be tested for various aspects. For example, steering wheels can be evaluated for their grip, dashboards can be verified for color, and consoles can be assessed for the amount of wear they show after use. The results gathered from these tests can provide insight into whether a design needs alteration.

Advantages of Rapid Prototyping

In the automotive industry, there is constant pressure to achieve higher performance standards, including those regarding fuel efficiency, aerodynamics, connectivity, and security. By employing rapid prototyping techniques, manufacturers experience the following advantages:

- Low material waste

- Can cost-effectively scale to production volumes

- Multiple finishing options like anodizing and powder coating

What Materials Work Best for Automotive Applications?

Thermoplastics

Choose from hundreds of thermoplastics including PEEK, acetal, or supply your own material. Maintain branding with custom colorant for qualified projects.

Thermoplastics

Choose from hundreds of thermoplastics including PEEK, acetal, or supply your own material. Maintain branding with custom colorant for qualified projects.

Thermoplastics

Choose from hundreds of thermoplastics including PEEK, acetal, or supply your own material. Maintain branding with custom colorant for qualified projects.

Thermoplastics

Choose from hundreds of thermoplastics including PEEK, acetal, or supply your own material. Maintain branding with custom colorant for qualified projects.