Valuable

Get valuable Market Promotion

Valuable

Get valuable Market Promotion

Valuable

Get valuable Market Promotion

Valuable

Get valuable Market Promotion

Valuable

Get valuable Market Promotion

Valuable

Get valuable Market Promotion

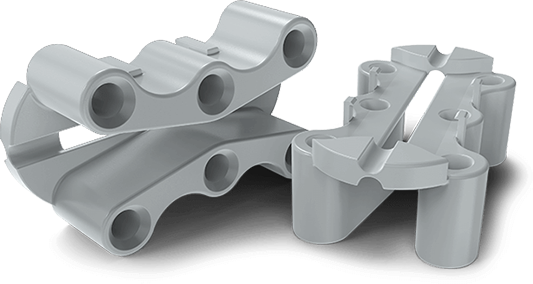

Finally, it’s possible to make small numbers of housings and enclosures without investing in expensive plastic injection mold tools. However, product developers should note that the corner radii of a machined part will not be the same as a corner made from an injection mold tool. There may be other slight design differences as well, so it’s best to consult us in advance.

Finally, it’s possible to make small numbers of housings and enclosures without investing in expensive plastic injection mold tools. However, product developers should note that the corner radii of a machined part will not be the same as a corner made from an injection mold tool. There may be other slight design differences as well, so it’s best to consult us in advance.

Finally, it’s possible to make small numbers of housings and enclosures without investing in expensive plastic injection mold tools. However, product developers should note that the corner radii of a machined part will not be the same as a corner made from an injection mold tool. There may be other slight design differences as well, so it’s best to consult us in advance.

CNC Machining Services

Unless otherwise specified by you, our standard tolerances conform to DIN-2768-1-fine.

Show your customers and investors a physical model of your product Demonstrate the appearance, dimensions, and features of your product Test the market with your product before production Save time and money by identifying and reducing design flaws Improve and streamline the production process Create multiple versions with different colors, surface textures, and finishing processes

Our partners at BioRep needed a quick-turnaround solution to make stem cell isolators in the fight against Covid-19. Star Rapid responded in a matter of days.

Although it’s possible to plastic injection mold Ultem, we used CNC milling and turning for this project. This is because the customer only needed a few parts and we had to produce them fast while also maintaining tight tolerances.

Read more >

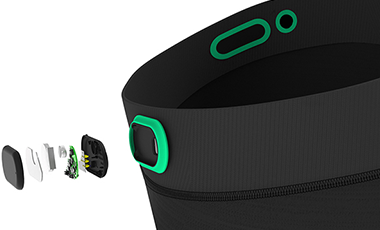

Myant approached us to help them develop a set of rapid prototypes for their major product introduction at CES 2018. These prototypes needed to be showroom quality, identical in fit and finish to eventual production versions.

Read more >

Our partners at BioRep needed a quick-turnaround solution to make stem cell isolators in the fight against Covid-19. Star Rapid responded in a matter of days.

Although it’s possible to plastic injection mold Ultem, we used CNC milling and turning for this project. This is because the customer only needed a few parts and we had to produce them fast while also maintaining tight tolerances.

Read more >

Myant approached us to help them develop a set of rapid prototypes for their major product introduction at CES 2018. These prototypes needed to be showroom quality, identical in fit and finish to eventual production versions.

Read more >